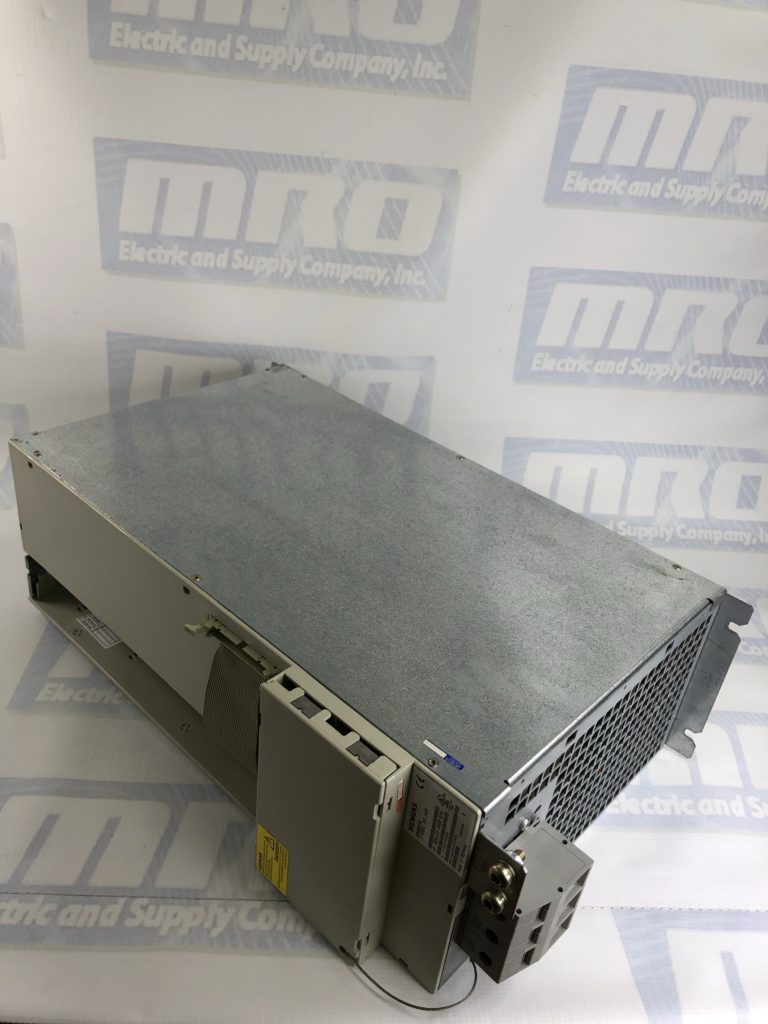

You can check out our previous blog post on the Control Techniques UNI3405 manual here for more information.

Cable lengths in excess of the specified values may be used in the UNI3405 configuration only when special techniques are adopted; refer to the supplier of the Drive.

The maximum cable length for the Unidrive UNI3405 configuration is reduced from that shown above under the following conditions:

-

- PWM switching frequency exceeding 3kHz in model sizes 3 and 4 — The maximum cable length is reduced in proportion to the increase in PWM switching frequency, eg. at 9kHz, the maximum length is 1/3 of that shown.

- High-capacitance cables – Most cables have an insulating jacket between the cores and the armour or shield; these cables have a low capacitance and are recommended. Cables that do not have an insulating jacket tend to have high capacitance; if a cable of this type is used, the maximum cable length is half that quoted in the table.

- A thermistor mounted on the heatsink monitors the heatsink temperature. If this exceeds 95 °C (203 °F), the thermistor will cause the Drive to trip. The display will indicate Oh2

- Intelligent thermal modelling estimates (by calculation) the junction temperature of the IGBTs. There are two temperature thresholds which cause the following to occur:

- If the first threshold is reached, the PWM switching frequency is halved in order to reduce dissipation in the IGBTs. (When the frequency is halved, the value of parameter 0.41 PWM switching frequency remains at the value set by the user; if the frequency is 3kHz or 4.5kHz, no halving occurs). Then at one second intervals, the Drive will attempt to restore the original PWM switching frequency. This will be successful if the estimated temperature has reduced sufficiently.

- If the estimated temperature has continued to rise and reaches a second threshold, the Drive will trip. The display will indicate Oh1.

You can get price and availability by emailing sales@mroelectric.com or calling 1-800-691-8511.