Coast to coast, the American landscape stretches from cityscapes to deserts. It’s no surprise that car preferences vary wildly across state lines. What might be a dream ride cruising the California coast—a sleek convertible with the latest tech—wouldn’t quite conquer the snowy peaks of Vermont. But one thing unites car owners everywhere: a deep affection for their four-wheeled rides.

Join us on a road trip unlike any other, as we explore the “dream car” of each state! We’ll delve into the features, styles, and comforts that Americans dream of, revealing what truly gets their engines revving. Buckle up, gearheads – this data-driven journey across the U.S. of A. is about to take you from coast to coast in search of the ultimate American dream car!

Under the Hood of State Preferences: Mapping Car Dreams

Colorful Choices in a Sea of Black

While black remains the most popular color choice overall and in 38 U.S. states, several states buck this trend. New Mexico stands out with its preference for blue vehicles, perhaps inspired by its famous clear skies. Meanwhile, Colorado opts for shades of green in their automotive choices – maybe as a testament to its forested landscape. Though the majority of states favor the classic black, these pockets of color diversity demonstrate the varied tastes of American drivers.

Sedan Strongholds

While SUVs dominate the dreams of many Americans, some states still show a preference for the classic sedan. Connecticut and Massachusetts stand out as sedan enthusiasts in our survey. This could be attributed to the region’s older cities, which have narrower streets and tighter parking spaces, making sedans a more practical choice for urban dwellers.

Comfort is King in the North

While many cars are tricked out with countless features, we asked Americans to rank the number one feature that’s most critical in their dream car. The importance of heated seats can’t be overstated for some northern states. Maine, New York, and Rhode Island all list heated seats as their top priority. This preference is likely driven by the harsh winters these states experience, making warm seats a daily necessity rather than a luxury.

Beyond heated seats, northern states also strongly prefer other comfort-enhancing features. For instance, New Hampshire and Massachusetts prioritize 4-wheel drive, likely a necessity for navigating snowy roads. Meanwhile, states like Illinois, Michigan, Minnesota, and Nevada all list remote start as their most desired feature, allowing drivers to warm up their cars from the comfort of their homes during the winter months.

Eco-Conscious Choices

21 states show a strong preference for hybrid vehicles, indicating a growing environmental consciousness. States like California, Connecticut, Massachusetts, and Washington all dream of hybrid cars. Interestingly, these states represent both coastal regions, suggesting that eco-friendly transportation might be a priority in these areas. However, many inland states, such as Illinois, Minnesota, and Nevada, also prefer hybrids, showing that this trend isn’t limited to the coasts.

Beyond State Lines: Decoding the DNA of America’s Dream Cars

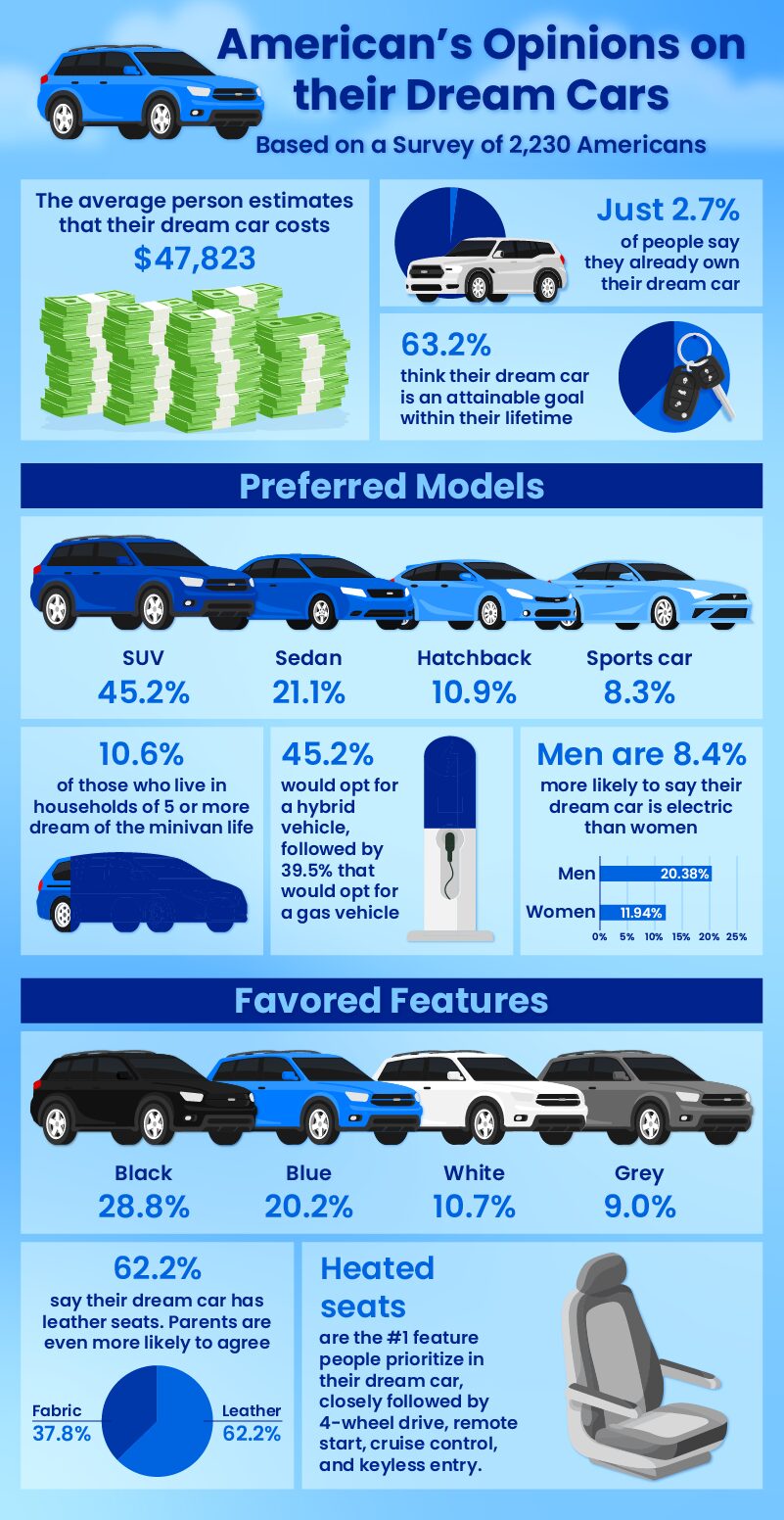

The average American’s automotive aspirations come with a surprisingly specific price tag: $47,823. This figure suggests that most people’s dream cars fall squarely in the luxury or high-end market, but aren’t quite in supercar territory. In fact, 63.2% believe their dream car is attainable within their lifetime, and 2.7% say they already own it.

When it comes to color, Americans seem to prefer their dreams in darker shades. Black leads the pack at 28.8%, with blue following at 20.2%. White and grey round out the top four, suggesting a preference for classic, understated colors.

SUVs dominate the dream car landscape, with 45.2% of respondents putting them at the top of their list. This preference for larger vehicles aligns with the growing trend towards spacious, versatile cars. Sedans come in second at 21.1%, followed by hatchbacks and sports cars.

While minivans might not be winning any cool contests, they have a dedicated fan base. Only 3.6% of overall respondents dream of minivans, but here’s where it gets interesting: those living in households of 5 or more are 6.5% more likely to fantasize about the minivan life. Minivans have the most fans in Indiana, with 1 in 10 Hoosiers saying it’s their dream car. It seems that practicality can indeed be the stuff of dreams for larger families.

Dark interiors are the clear winner, with 71.1% preferring them over lighter options. When it comes to seating, leather reigns supreme, with 62.2% opting for this luxurious touch. Interestingly, parents are even more likely to prefer leather seats (68.3%), possibly valuing their durability and ease of cleaning.

The shift towards more eco-friendly options is evident, with 45.2% choosing hybrid vehicles as their ideal. Traditional gas vehicles follow closely at 39.5%. There’s a notable gender divide when it comes to electric vehicles: men are 8.4% more likely than women to dream of an electric car.

Automatic transmissions are overwhelmingly preferred, with 89.2% of respondents choosing them for their dream cars. This preference for convenience extends to the most desired features: heated seats top the list, followed closely by 4-wheel drive, remote start, cruise control, and keyless entry.

Driving Dreams: The Road Ahead

Our journey through America’s automotive aspirations reveals a nation of diverse dreams, practical considerations, and evolving preferences. From the sun-soaked convertibles of Nevada to the heated seats prioritized in the Northeast, it’s clear that our ideal vehicles are as varied as the landscapes we drive them through.

From the sun-soaked shores of California to the rugged mountains of Alaska, it’s clear that the American dream car is as diverse as the nation itself. While these automotive aspirations may vary by state, one thing remains constant: the need for reliable, efficient, and powerful machinery.

At MRO Electric, we understand the importance of keeping operations running smoothly. Our expertise in providing top-tier controls and automation solutions is essential for industries across the country. Just as drivers rely on their vehicles to get them where they need to go, businesses depend on our products to achieve their goals. Let MRO Electric be your partner in powering progress. Contact us today to see how our solutions can support your automation needs.

Methodology

These insights are based on a survey of 2,230 Americans. The survey was run in July of 2024. Alaska, Montana, North Dakota, South Dakota, Vermont, Washington, D.C., and Wyoming were omitted from our research due to insufficient sample sizes.