Relays are an often overlooked, but pivotal component in modern technology, serving as the silent orchestrators behind a wide range of electronic operations. Whether controlling high-power machinery or everyday devices, relays play a crucial role in transferring signals and power without direct electrical connections. They are used across a wide range of devices and applications, from industrial automation to consumer electronics, and understanding how they work is key to fully utilizing their capabilities

Essentially, electrical relays control one electrical circuit by opening and closing contacts in another circuit. When a relay contact is normally open (NO), the circuit is open when the relay is not energized. Conversely, when a relay contact is normally closed (NC), the circuit is closed when the relay is not energized. Applying electrical current to the relay changes the state of these contacts, thereby controlling the connected circuit.

What Is a Relay?

A relay is an electrically controlled switch that has the ability to turn a circuit on or off. Depending on the application relays can do a number of things. Relays can be used as electrical switches to turn things on and off, or as amplifiers to convert smaller currents into larger ones. They can also be used to control a circuit with a low power signal or when multiple circuits need to be controlled by a single signal.

There are two kinds of relays, electromechanical and solid state. In this post, we will be focusing on electromechanical relays and how they work.

Why Are Relays Important?

Electrical relays are crucial because they enable the control of high-current loads using a small amount of electrical current. Relays apply voltage to the coil, which causes a low current to flow through it. This allows a larger current to pass through the contacts and control the electrical load. Relays are essential for applications where low-power control signals need to command high-power circuits.

What Are the Parts of a Relay?

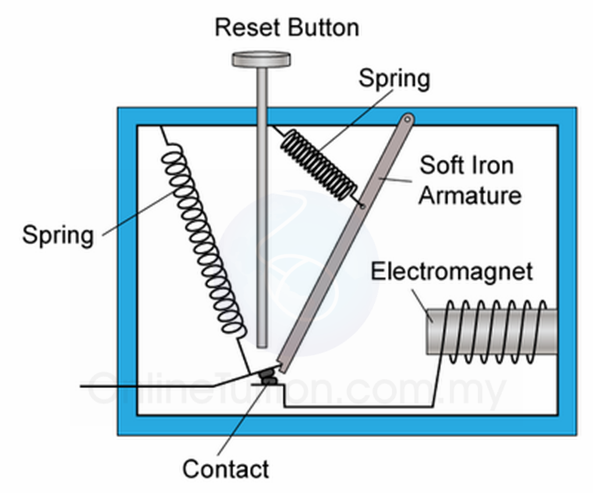

Armature– is a basic metal piece that is balanced on a pivot or a stand. It is considered the moving ‘arm’ of the relay. It makes or breaks the connection with the contacts connected to it.

Spring– is connected to one end of the armature and pushes the armature back into place if no current is passing through.

Electromagnet– is a metal wire wrapped around a metal core. The wire does not have magnetic property but can be converted into a magnet with the help of an electrical signal.

Yoke– is a small metal piece affixedon a core which attracts and holds the armature when the coil is energized.

Contacts– conductive material that exists within the device whose physical contact opens or closes a circuit

A break refers to the number of locations on a circuit that a switch can make or break the flow of current. In electromechanical relays, there can be single breaks and double breaks. A single break is usually used with low power devices while a double break is usually used with high power devices.

A pole refers to the number of circuits that relays can pass through a switch. A single pole contact carries current through one circuit, while a double can carry it through two.

A throw refers to the number of separate wiring paths. For example, a triple throw switch can be connected to one of three contacts instead of one.

How Do Relays Work?

https://www.electronics-tutorials.ws/io/io_5.html

In an electromechanical relay, a small circuit has the ability to switch a larger circuit on or off through contacts by using an electromagnet. Some contacts come in different configurations depending on the use of the relay, namely, normally open relays and normally closed relays.

With a normally open (NO) relay, contacts are open when there is no current passing through. Once power is presented, the electromagnet will be activated. When charged, the electromagnet creates a magnetic field that attracts the armature and closes the contacts.

With a normally closed (NC) relay, contacts are closed when there is no current passing through. Unlike normally open relays, when normally closed relays become activated, the circuit will open and cause the current to stop flowing.

What Are the Different Types of Relays?

Electromechanical relays can be broken down into the following distinct categories: general purpose relays, machine control relays and reed relays.

General Purpose Relays

General purpose relays are electromechanical switches that typically function via a magnetic coil. Using an AC or DC current, general purpose relays often run at voltages such as 12V, 24V, 48V, 120V and 230V. Additionally, they can command currents ranging from 2A-30A. These relays are sought after due to them having a multitude of switch configurations and being cost-effective.

Machine Control Relays

Like general purpose relays, machine control relays are operated by a magnetic coil. Typically used to control starters and other industrial elements, these relays are robust. While this gives them greater durability, it also means that they are less economical than general purpose relays. However, with additional accessories and functionality, they have an advantage over general purpose relays.

Reed Relays

Reed relays consist of two reeds, which can open or close when controlled by an electromagnet. These small relays can operate up to eight reed switches, which are typically found inside of the electromagnetic coil. When the magnetic force is removed, the reeds return to their initial open position. Since the reeds are only a short distance apart from each other, reed relays work rather quickly. There are many benefits of using a reed relay, as their hermetic seal prevents the passage of contaminants. Additionally, this seal enables reed relays to have dependable switching.

There are many things to consider when choosing a relay for a project. Lifespan, operating environment, mechanical loads, size, and number and type of contacts are all important factors in choosing the right relay.

What Are the Pros and Cons of Using Relays?

While electromechanical relays have a variety of uses, different applications require different automation devices, and electromechanical relays may not always be the best fit. To help you determine if an electromechanical relay will work for you, we have highlighted some of the advantages and disadvantages below.

Advantages

- Fast operation and reset

- More definitive ON/OFF

- Simple and most reliable

Disadvantages

- Suffers the effects of age

- No directional features

- Needs a large amount of input power to operate

What Is a Relay Used For? Relay Applications

Relays protect electrical systems by preventing and reducing the damage to the connected equipment from over currents and voltages. Relays protect a wide range of equipment by detecting and isolating faults in a power transmission and distribution system.

Since electrical relays can control a high-voltage circuit using a low-voltage signal, they can help prevent damage to valuable electronics and components, including modems, amplifiers, and even the starter in your car.

Other applications for relays include:

- Automotive

- Appliances

- Lighting systems

- Telecommunication components

- Industrial controllers

- Electrical power protection systems

- Traffic control

How Do You Test a Relay?

While relays are generally dependable, they can still experience faults like any other component. Thankfully, testing a relay is a relatively straightforward process– all you need is a multimeter. Read on to learn how to identify a faulty relay step-by-step.

- Locate the relay: Find where the circuits enter and exit the relay. This region is typically marked by pins or terminals.

- Check for voltage: With the multimeter set to measure voltage, probe the point where the relay plugs into the circuit. If it does not detect any voltage, inspect the associated fuse or switch for any defects that might interrupt the power supply.

- Test ground connection: If voltage is present at the connection point, switch the multimeter to the continuity or resistance function and check for a good ground connection on the opposite side of the relay. A faulty ground can cause the relay to malfunction.

- Verify power source: After successfully checking for voltage and testing the ground connection, check the voltage where the relay connects to the battery or another power source. If the multimeter detects no voltage here, it suggests a potential issue with a fuse or circuit breaker.

- Test component connection: Use the multimeter’s continuity function to ensure a strong connection between the relay and the component it controls. If continuity exists and the previous steps did not reveal any other faults, it is likely a defective relay.

How Do You Identify a Faulty Relay?

Although relays are considered reliable mechanisms, they do have the capability of failing. Determining whether you have a faulty relay is simple and can be easily identified with the help of a multimeter.

Here are a few tips on how to use your multimeter to test a relay:

- Remove the relay from the fuse box or vehicle.

- Determine where the input and output points of the circuit are located on the relay.

- Make sure your multimeter is set to ohm.

- Connect the leads of the multimeter across the entrance and exit pins to determine resistance. Ideally, you’ll see a reading between 50 to 120 ohm.

- If your multimeter has a reading of Open or Out of Range you may have a defective coil winding and the relay will need to be replaced.

- If the reading looks good, you’ll want to connect the leads in between the switch pins. You should see a reading of OL or Open.

MRO Electric and Supply has an extensive inventory of relays in stock. Please email sales@mroelectric or call us at 800-691-8511 for a quote.